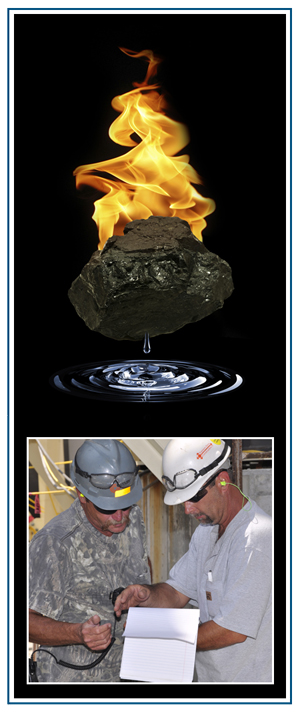

Exhaustive Gasifier Refractory Services from Thorpe

Thorpe’s involvement in gasifiers began in 1977 when we installed the linings in two new units in Deer Park, Texas. Since then, we’ve participated in numerous new gasifier projects in the Gulf Coast Region as well as others across the US and internationally. Our history includes equipment from various OEMs and lining designs for both solid and gas-fueled units.

While the performance of refractory maintenance on these units has become a big part of our business, we also help owners by maintaining their spare lining material inventory. These are high quality, special-shaped brick which typically have long delivery times. Our familiarity with the wear areas of gasifiers allows us to recommend to our customers the appropriate materials to inventory for emergency purposes.

Advantages of relying upon Thorpe for gasifier refractory work include:

- A crew that’s familiar with the unique installation requirements of gasifier linings required by the high temperature, high pressure and corrosive operating conditions.

- Years of experience in complicated brick installations across many industries.

- A large resource of highly qualified bricklayers and experienced field laborers in gasifier and other complex brick constructed units.

- Refractory engineers on staff to provide detailed design upgrades to improve refractory lining problems when needed.

- The ability to manage and maintain appropriate inventories of the special refractory shapes utilized in gasifier linings.

- Ongoing work experience in coal, petroleum coke and gas-fueled units.