In-House Acid Plant Lining Design and Installation

It’s no secret that Acid Plant linings are inherently challenging due to the corrosive nature of the operations, equipment size and geometry, complex connections, and the critically important temperature and mechanical issues involved. For those reasons, refractory and acid contractors must have a thorough understanding of the corrosive effects on both steel and refractory materials, the thermal profiles through the lining and the mechanical stability of the construction.

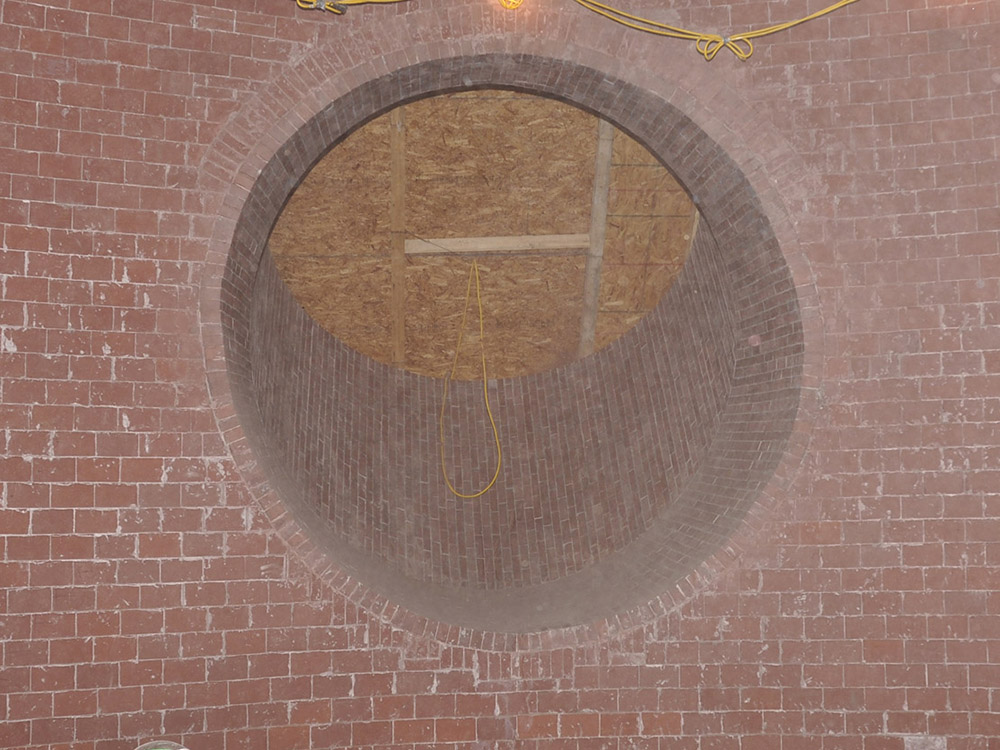

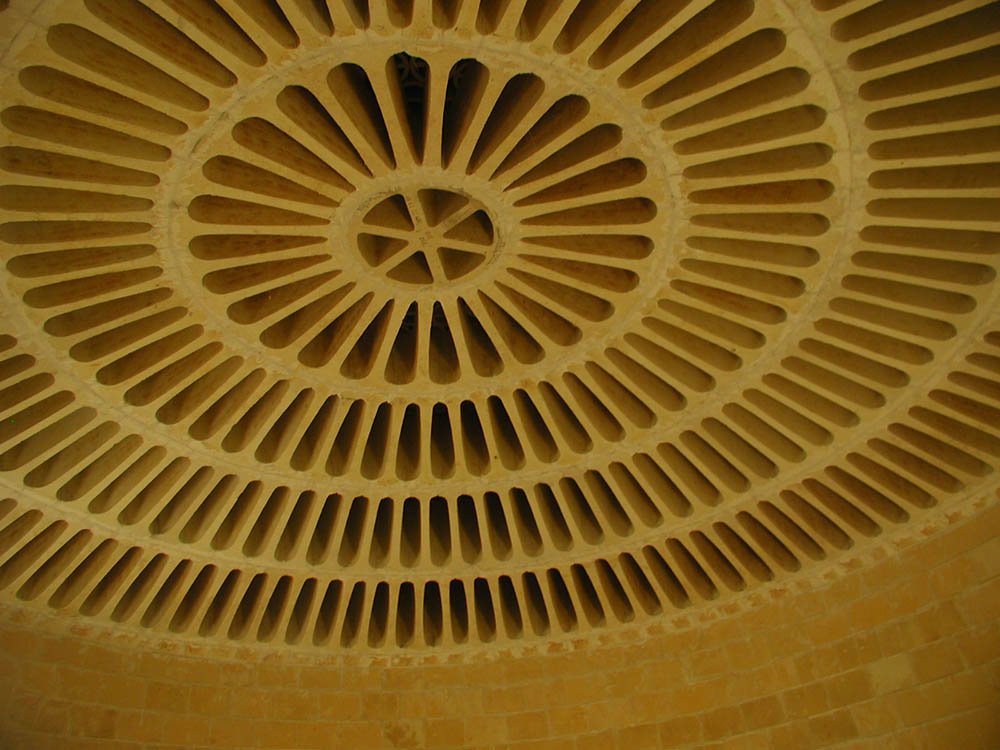

Keeping our core focus on the optimized performance of Acid Plant linings, we exist as one of the few refractory and acid masonry contractors with the in-house capability to design and install reliable acid plant linings. We employ our experienced engineering specialists and draftsmen to prepare detailed construction drawings for each project. Many of our design concepts and brick construction details are routinely replicated in the industry through various OEM, licensor and owner specifications.

In addition to our engineering capabilities, we maintain a large resource of highly skilled bricklayers, craftsmen and field laborers experienced in acid pant and other severe service lining applications. Since 1954, Thorpe has held a strong reputation in Acid Plant linings. As a result of our unique capabilities, we’ve had the opportunity to expand our work in Acid Plants across North America and selected international markets.

Typical Equipment for Acid Plants include:

- Sulfur furnaces

- Outlet ducts & jug valves

- Waste heat boiler vestibules & tube sheets

- Acid towers

- Pump tanks

- Converters

- Acid pads

- Ductwork