Large Diameter Non-Metallic Tanks

Thorpe is unsurpassed as the leader in large diameter, non-metallic tanks and equipment. Our team is able to provide stamps to both ASME RTP-1 and ASME Section X standards for our custom engineered and manufactured equipment. We shop-manufacture and ship equipment up to 16’ diameter. As the developer of ring oblation of tanks, in conjunction with our field service crews, we supply and field erect equipment up to 57’ diameter.

The key to providing high quality, cost effective large diameter tanks is the turnkey capability to design, shop manufacture and field erect the equipment. Oblation techniques developed by our manufacturing facilities allows for the transport of this equipment to the jobsite for a cost effective field erection by our field crews. Please see the short movie below to better understand these unique capabilities.

Mix Tanks and Agitated Tanks

As a custom manufacturer, all of our process equipment is built to order. We manufacture equipment to any specification quickly, accurately and economically. Process equipment is built for customer’s needs in either unstamped industry standards (such as ASTM D3299 for filament wound equipment and ASTM D4097 for contact molded equipment) or stamped FRP (Fiberglass Reinforced Plastic) tanks made under the scrutiny of ASME RTP-1 or ASME Section X.

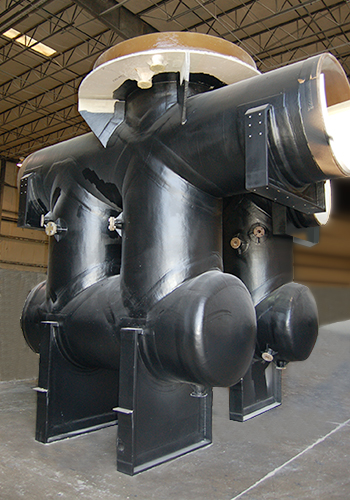

Scrubbers

Our team is highly experienced in the expert design and manufacture of a wide range of fume scrubbers and components. Industrial scrubbers/absorbers, shells and vessel internals have been manufactured using FRP for many years due to the corrosion resistance and dependability of these materials.

Thorpe’s FRP scrubbers and scrubber components have been used in a wide range of industries including Power & FGD, Metals & Mining, Chemical Processing, Cement, Water Remediation and Odor Control.

With the proper material selection, FRP can provide long term corrosion resistance and low maintenance cost in applications in which carbon steel, stainless steel, duplex stainless steel, coatings and linings are simply not a long term solution. FRP material is also a more economical solution than high-nickel content alloys in scrubber environments containing elevated chloride concentrations or wet acids.