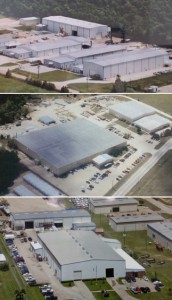

Thorpe’s team has been the industry leader in Fiberglass Reinforced Plastic (FRP) tank design and manufacturing since 1957. Our facilities provide industry standard and custom designed solutions for the manufacture of fiberglass and thermoplastic specialty shapes, rubber lined pipe and vessels, polymer concrete trenches and sumps, structural components, flanges and fittings, among others. We maintain three manufacturing facilities with a combined 400,000+ square feet of shop space located in three states. Each facility provides a shop-controlled environment for the manufacture of industrial non-metallic equipment parts and components. Our manufacturing locations provide for easy quality control and preplanned straight time work to reduce downtime and project cost. Our ability to service local maintenance customers as well as our production capacity to handle world scale projects across our manufacturing plants are unmatched.

First in Certification, Innovation and Quality

Thorpe team holds certifications for both ASME RTP-1 and ASME Section X; the first jointly held ASME certifications by any company in the business. Leadership begins with safety, but is always best reinforced by quality. Our team also brings several industry “firsts” in large diameter tank technology. We were the first to develop ring oblation of tanks for field assembly and were the first to deliver and erect field tanks to 57′ diameter.

Process equipment is unique to its specific application, therefore engineered customization is critical. Thorpe has the experience, engineering capabilities and knowledge to make the most cost effective and performance based process equipment available.

Our engineers design and manufacture FRP tanks, scrubbers, pipe, duct, stacks and chimney liners in a wide range of sizes, shapes and configurations. While cylindrical shapes are often most economical and practical, we offer rectangular and other configurations that may better suit the particular needs of any process problem.