Combat Unnecessary Sulfur Recovery Unit Failures

Thorpe is in the business of combatting equipment failures. Today, the demands on Sulfur Recovery Units (SRUs) are more severe than at any time in the past. These units undergo higher operating temperatures, more throughput, O2 enrichment, swing operations (part-time air/O2), faster startups/shutdowns and stricter emission limits. The materials and design approaches of the past often result in unreliable performance, extended timelines and expensive maintenance requirements. The size of today’s units combined with higher operating temperatures and swings, as well as the vessels’ high and low-temperature corrosion points, create complex issues requiring careful consideration to optimize refractory reliability and performance.

Some of the critical factors that affect refractory reliability and life cycle cost include:

- Air operation &/or O2 enrichment

- Vessel size or diameter

- Shape or geometry (ie: heads, cones, transitions, flat walls, etc)

- Hot face material quality & thickness

- Backup material quality & thickness

- Lining construction details

- Shell corrosion points (high and low)

- Burner harmonics &/or flame impingement

- High-temperature refractory deformation

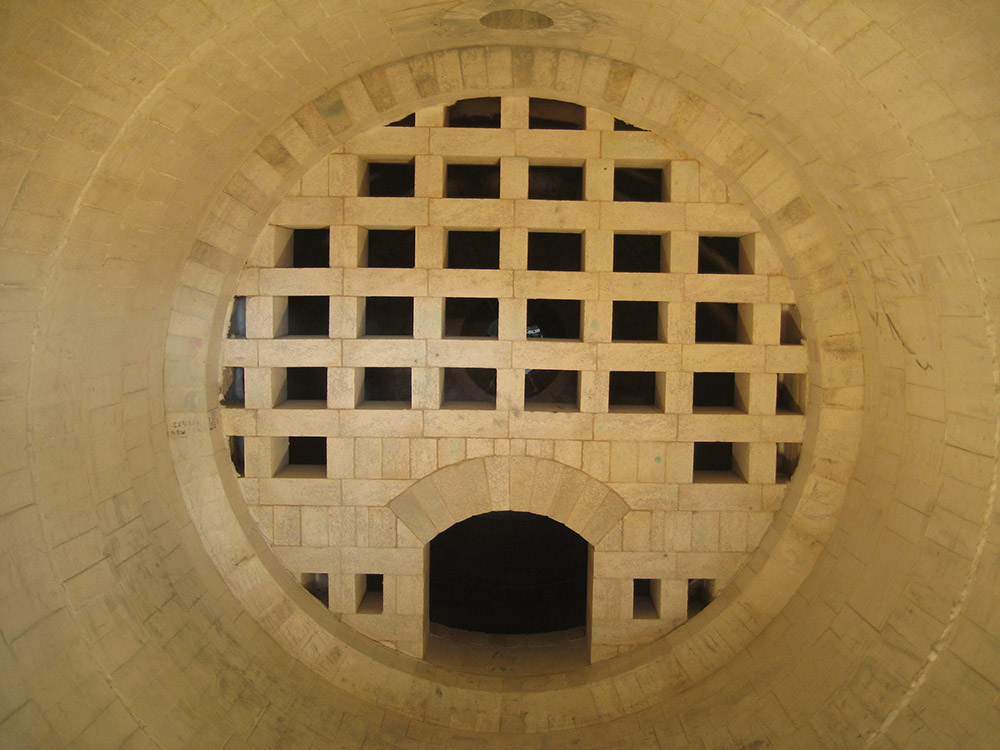

- Checkerwall/choke ring construction details

- Reducing atmospheres

- External thermal protection system

- Expansion accommodation (radially and linearly)

- Keying action (self-supported lining designs)

- Upset conditions (thermal and pressure-related events)

- Temperature measurement means (internal and external)

- Quality and skill of the installation contractor

Thorpe’s engineers combine over 60 years of experience in material science and accepted engineering practices to develop engineered linings. We are not limited to any single supplier for material options but can design solutions utilizing the most appropriate materials for the job. Thorpe’s designs and recommendations are based on solid engineering principles and real-life findings from our field inspection and maintenance activities. We have the capability to take any design, and build it to last for decades.

Our capabilities include:

- Refractory failure analysis

- Existing system evaluations (for weak links in the lining)

- Heat transfer calculations for different surface configurations and orientations

- Proprietary thermal software modeling program (radiant and convective heat loss) for cylindrical horizontal shrouded vessels

- Detailed AUTOCAD engineered construction/installation drawings

- Complicated brick lining designs (heads, cones, connections, nozzles, mixers, etc.)

- Proprietary high-temperature testing regime for severe service brick products

- Expansion allowances and joint designs

- Lining stabilization systems

- Anchoring systems and layout details

- Stress calculations

- Bill of Materials

- Field Technical Advisors to assist the installation of our designs

Reaction furnaces have the capability of melting the best refractory materials available today. This includes air-operated units during upset conditions or uncontrolled operation. Our goal is to optimize lining systems through the best material selection, engineered linings and proper installation.