The FRP Corrosion Services Your Project Needs

Tanks and Vessels

Thorpe’s advanced problem solving capabilities combined with our engineering empowered solutions make us uniquely capable of executing maintenance for tanks and vessels. Additionally, we have been dually accredited in ASME RTP-1 and ASME Section X codes since 1975. Our team’s extensive knowledge and experience extend to the execution of site erection of large diameter tanks and vessels in addition to the maintenance, repair and inspection of existing vessels. Our FRP Corrosion Specialists are skilled at developing unique methods to properly handle access issues commonly encountered when working in existing plants––all created to best fit budgets and project schedules.

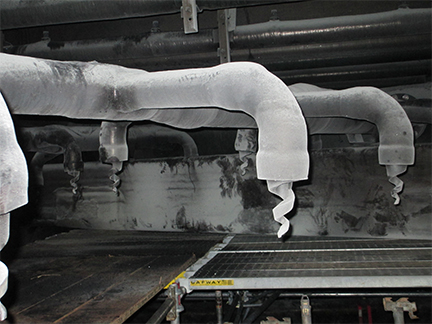

Piping

When we say there’s no piping project too big or small for our team, we mean it. Thorpe offers both planned and emergency inspections or repairs of existing lines. With the combined fabrication capabilities of our plants, we’re equipped to produce large quantities of first-class fabricated pipe and fittings in a very short amount of time to best support all field activities. We can spool these parts in our shop to shippable dimensions and delivered to the site for final fit-up and installation by our field crews.